Light Industry

Drive Productivity & Sustainability Through Innovation

The Light Industry sector includes manufacturers of a wide variety of products from automobiles to microelectronics, plastics to parts, and an assortment of other business and consumer goods. Manufacturing facilities use water in their everyday production processes and are concerned with environmental compliance, sustainability, profitability, and productivity. That is why an experienced water treatment partner is an essential piece of the manufacturing puzzle.

With innovative technologies aimed to create shared value, Kurita America uses a Total Solutions approach that incorporates chemical, equipment, engineering, and services to immerse, architect, deliver, and evolve, called "The Kurita Way.”

Segments We Serve

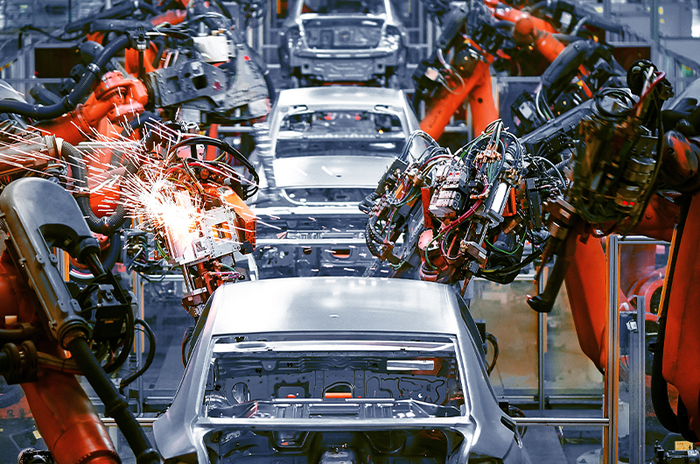

Kurita America, as part of the Kurita Group, has established itself as a highly competent partner for all issues concerning water and wastewater management. With over 60 years of experience working with the automotive industry, we offer the most technically up-to-date water and process treatment solutions.

In many cases, effluent water from one process can be suitable for reuse in another process if given appropriate treatment. Kurita America helps customers meet sustainability requirements and reduce costs through reuse by lowering charges for water consumption and effluent disposal, decreasing energy costs due to the recovery of heat in recycled wastewater, and reducing CO2 emissions.

Other manufacturing segments that Kurita America serves:

- Aeronautics

- Ammunition

- Commercial Laundry

- Concrete

- Construction Materials

- Containers

- Industrial Gas

- Medical Device

- Pharmaceutical

- Plastics

- Textiles

- Transportation and Storage

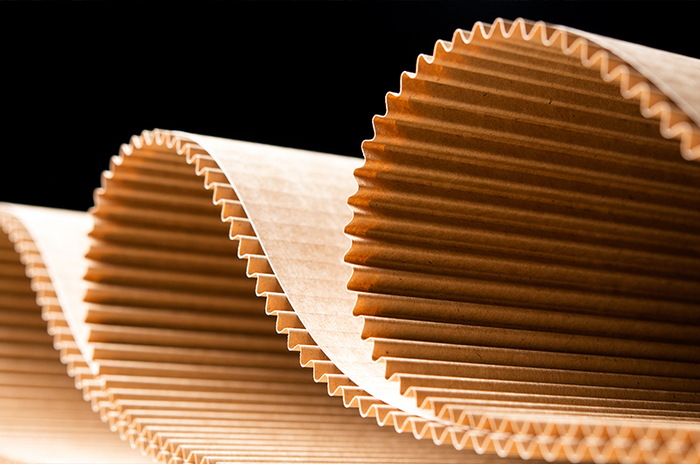

As the key component within the system, any improvements within the vulcanization process can increase productivity and profitability. Kurita America works with tire and rubber producers to design a water treatment program that addresses production and sustainability key performance indicators (KPIs).