Biofuels Process Chemistries

Kurita America's Process Technologies team supports the fuel ethanol industry with innovative chemistries designed to reduce air pollution, prevent deposits, prevent corrosion, and enhance fermentation and corn oil recovery, in order to improve fuel ethanol manufacturer profitability. Kurita America's flexible approach to remotely monitoring and analyzing operational data brings additional value to plant operations, as operators are engaged with Kurita America 24/7 to mitigate risks that could lead to unexpected downtime.

Key Biofuels Chemistries

Yeast health suffers when bacterial infections consume sugar meant to feed yeast and generate organic acids that stress yeast. Unhealthy yeast results in a decreased ethanol yield. Kurita America provides two popular antibiotics, penicillin and virginiamycin, with full technical support and competitive pricing.

The ProClean product line offers alternatives and additives designed to enhance the evaporator and other back-end CIP processes. These products are regularly used to supplement current CIP programs and provide optimum results, returning contacted surfaces back to “like new” bare metal. We have documented excellent results utilizing ProClean 335/345/336 and ProClean 815 products in evaporator CIP events. As with all application recommendations, a firm understanding of the process and nature of the fouling supports the development of a CIP protocol to produce the best site-specific results. ProClean 335/345/336 products “prepare” the deposit for the caustic CIP cycle. ProClean 815 is an additive to the caustic cycle that greatly enhances effectiveness. At the recommended usage rates, these products are acceptable for use in FSMA regulated ethanol plants.

These products will not unplug tubes or lines, but when added to a fouled system -combined with proper time, temperature and agitation - the following benefits can be realized:

- Reduction in CIP events leading to savings in chemicals like caustic and sulfamic acid.

- Improved water balance across the process

- Increased effectiveness of CIP events

- Reduction in hydro-blasting events.

- Reduction in acid usage between CIP events.

- Reduced energy consumption, due to cleaner tube surfaces

CorrPro is a family of final product corrosion inhibitors with enhanced corrosion, handling and pHe buffering properties.

As many ethanol producers are investing in corn oil recovery (COR) equipment platforms, COR additives are found to be a cost-efficient means of aiding mechanical separation/recovery and increasing overall COR yield. The portfolio of COR line of corn oil recovery products is designed to provide the right product for the plant-specific COR platform and operating conditions. The products are easy-to-feed liquids available in either tote or bulk delivery quantities and come with a self-contained chemical metering skid.

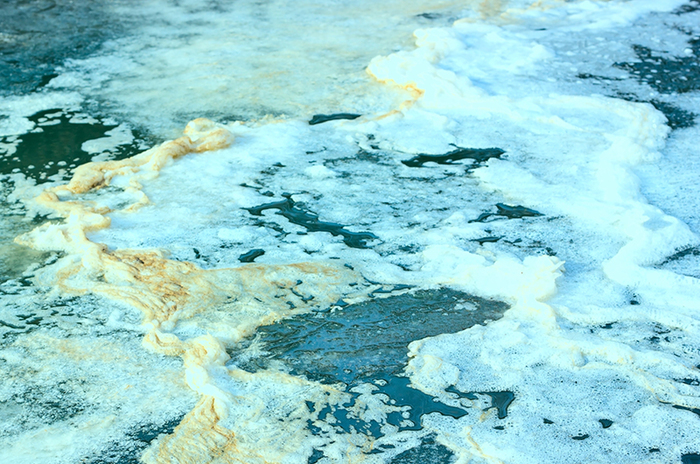

The ProHib product line is comprised of scale inhibitors designed to prevent deposit formation in evaporators across a broad spectrum of foulants - including Oxalates, Carbonates, and Magnesium Phosphate deposits. Upon plant operating data review by Process Technologies personnel, ProHib recommendations are based on a firm understanding of the fouling tendencies specific to each facility.

Kurita America has a complete line of Food Grade antifoams acceptable for use in Fuel Ethanol production.

VOxOUT 70C is a “fermentation friendly” CO2 scrubber chemical additive treatment designed to enable a plant’s ability to meet Hazardous Air Pollutants (HAPs) when unable to meet compliance via mechanical scrubbing alone. VOxOUT 70C replaces the sodium bisulfite with ammonium bisulfite and a proprietary catalyst that results in a quicker and more complete conversion of the acetaldehyde resulting in significantly lower bisulfites being sent to fermentation.