A United States Midwest dry grind fuel ethanol plant requested Kurita America to assist and implement production efficiency improvements within their plant. After an in-depth performance evaluation, the Kurita America Process Technologies team identified a number of opportunities to improve efficiencies and output quality, after observing limited plant throughput due to slurry flow restriction, plant downtime for equipment cleaning-in-place (CIP), increased chemical and energy cost as well as reduced co-product quality.

From their assessment, the Process Technologies team applied a unique patented process deposit control technology, pHytOUT. Developed specifically for the biofuels industry, our pHytOUT Technology is a liquid deposit control inhibitor typically added to fermenters. This easy to feed chemistry can reduce an ethanol plant’s dependency upon sulfuric acid (as a means of depressing pH and inhibiting the formation of specific deposits) while providing an overall process fouling inhibitor package. The plant undertook an extended no-cost trial of the pHytOUT Technology with considerable data collection and review.

The dry grind fuel ethanol plant experienced significant production efficiency improvements after implementing the pHytOUT Technology. The plant saw an increase in beer feed by 7% and associated >1.5 million gallons per year increase of denatured gallons per year in production. In addition, lowering pressure drops across the beer/mash exchanger were demonstrated by the control valve position.

The dry grind fuel ethanol plant experienced significant production efficiency improvements after implementing the pHytOUT Technology. The plant saw an increase in beer feed by 7% and associated >1.5 million gallons per year increase of denatured gallons per year in production. In addition, lowering pressure drops across the beer/mash exchanger were demonstrated by the control valve position.

Previously, manual cleaning was required to restore slurry flow every four to seven months, this required shutting down the front-end operations for three hours with ten added man-hours of effort during each event. At that time there was an increasing trend in the first effect steam pressures arrested and reversed, even with higher rates. After 51 days of using the pHytOUT Technology, piping was opened and inspected: from using pHytOUT Technology the piping was 99.9%+ open versus less than 90% open after previous manual cleaning.

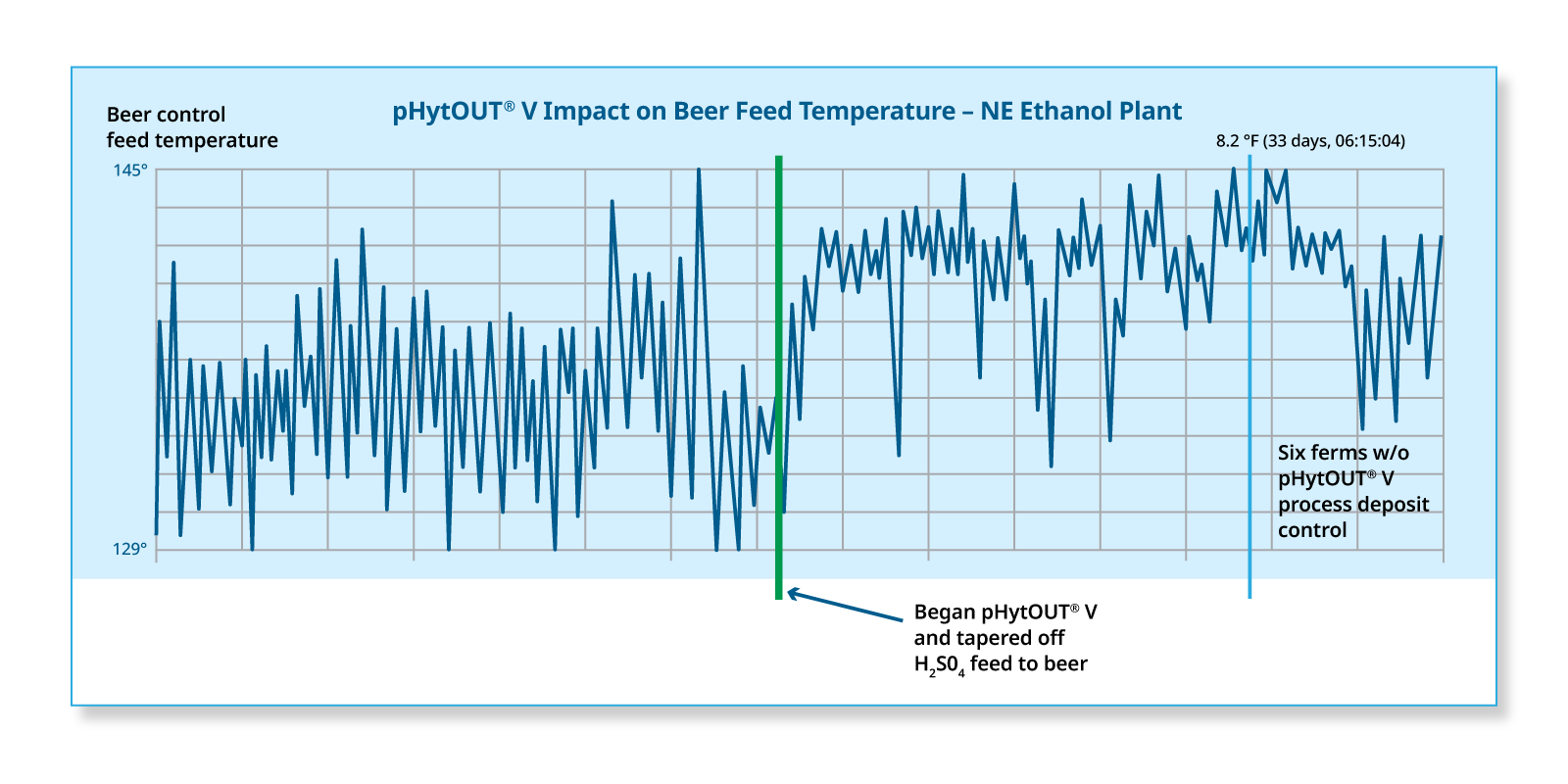

Many other process improvements were realized. The fermentation finish had less dependence on continued fermentation in the beer well with the beer feed temp increasing by 7°F, saving 2,600 MM British thermal units (BTU) per month. In addition, the effect steam demand reduced by 2,000 to 2,500 pounds per hour, the cook water rate increased by 22 gallons per minute (gpm) and temperature increased 5 degrees Fahrenheit (F), saving 1,970 MM BTU per month at 85% boiler efficiency. Annual technology application costs returned in 100 days.

Also, the sulfuric acid to beer feed discontinued, yet the heat exchange improved. Sulfuric acid savings of 8,300 gallons per month were seen with improved operational safety from reduced acid handling. Coproduct sulfur (dry matter basis) reduced from ~0.6%  to ~0.3%, decreasing >1.5 million pounds per year in co-product sulfate and >450,000 pounds per year as sulfur. Due to the reduction in sulfuric acid use in the exchanger train, alleviated wear on mechanical components, distillation and evaporators was reduced, resulting in a decrease in maintenance time and potential hazards during repair of these components.

to ~0.3%, decreasing >1.5 million pounds per year in co-product sulfate and >450,000 pounds per year as sulfur. Due to the reduction in sulfuric acid use in the exchanger train, alleviated wear on mechanical components, distillation and evaporators was reduced, resulting in a decrease in maintenance time and potential hazards during repair of these components.

Kurita America solves the root cause of the facility problems by integrating chemical, engineering, equipment, and service into one tailored package, unique to your company. Pairing this approach with the best engineers in water treatment and extensive dry grind operational experience, we have a proven track record in the fuel and ethanol industry solving tough challenges while delivering an immediate and long-term return on investment (ROI).

Biofuels Plant Sees Return on Investment After 100 Days with pHytOUT® Deposit Control Technology