A large food and beverage facility in the United States was facing increased costs from hauling away a full dumpster of sludge every week. The facility’s wastewater came from their production process, and the organic materials needed to be separated before being discharged back to the city. The costs for these types of services can vary between $600 and $1,500 per trip to dispose of the sludge, but costs can vary depending on sludge dewatering capabilities and region. Facility costs were estimated between $31,200 to $78,000 annually to dispose of sludge.

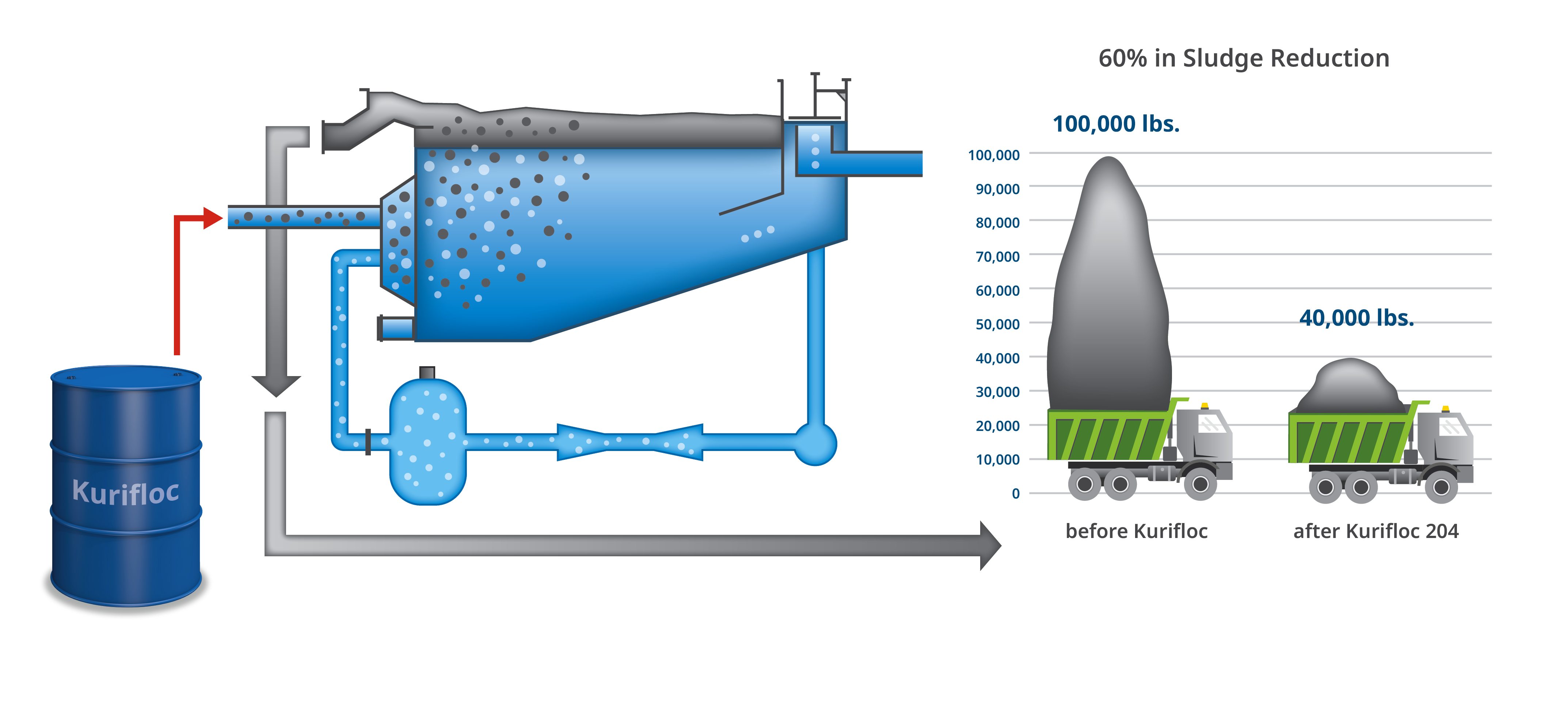

To aid in the liquid-solids separation (LSS), the incumbent water treatment provider was feeding an inorganic coagulant with a dosage of about 500 parts per million (ppm). This resulted in over 100,000 additional pounds of sludge being produced per year.

The facility sought alternative solutions to their challenges, and after a thorough review of the facilities operation and rigorous jar testing, Kurita developed a program that included Kurita’s Kurifloc technology. Kurifloc 204 is an organic coagulant that is fed at a much lower rate than traditional inorganic coagulants and is not toxic if overfed. Kurifloc 204 worked for this customer for a couple reasons.

Because the facility was producing different products, their production wastewater was highly variable. Water going into the treatment process varied in pH and temperature. This typically requires a higher feed rate of an inorganic coagulant to treat the production wastewater. Kurifloc 204 operates effectively in a wide pH and temperature range, allowing the operators to set the feed rate at a baseline dosing much lower on average than the feed rate of the inorganic coagulant. The facility was treating their water through several tanks to remove the major contaminants, and the sludge that was produced was sent to the dewatering process. Using Kurifloc the facility used less coagulant, saw better performance through their LSS process, and were able to produce and have to process less sludge.

Kurita worked with the plant to track the performance of the new chemical program. Validating that this was the best solution by measuring the dissolved air flotation (DAF) performance, sludge production, and chemical-use rate.

With Kurita’s Kurifloc program in use, the plant saw immediate results in reduced sludge generation and excellent solids removal:

-

A 60% reduction in sludge handling costs due to reducing the number of haul offs from fifty-two annually to an estimated nine annually.

-

Treatment results have consistently been averaging 100 and less nephelometric turbidity unit (NTUs), which is well under the required discharge treatment target.

-

The facility has implemented a sampling and testing program with Kurita, improving tracking and system adjustments based on biological oxygen demand (BOD), chemical oxygen demand (COD), total suspended solids (TSS), and pH.

By implementing Kurifloc 204 technology and working with the Kurita team to find a solution, the site minimized sludge disposals, program chemical costs, and improved results. This was recognized as an estimated annual savings of over $100,000 and more consistent and effective water treatment.