A food processing facility in the Upper Midwest was experiencing an upset due to a breakdown in their process equipment and production changes, which allowed for a high level of fats, oils, and grease (FOG) to pass into their waste stream. The additional FOG that was discharged into the aeration basin was not sufficiently removed during the primary treatment. The increased loading to the aeration system put a strain on the active bacteria in the system and decreased treatment efficiency. With FOG and other contaminants not being effectively removed, FOG began to layer in the aeration basin and created a 2-foot-thick fat cap. Therefore, the wastewater could not be discharged to the city and was redirected to the customer’s holding ponds. If the problem was left untreated, then the customer would have continued poor contaminant removal, increased surcharges, and extended recovery times of four to eight weeks. The customer already had a long-term partnership with Kurita America and the local representative, who had been providing bioaugmentation solutions for over five years. Bioaugmentation is the addition of specific bacteria to stabilize and improve the efficiency of biological treatment systems, including removal of FOG and soluble biological oxygen demand (BOD) and other contaminants.

At the customer’s facility, Kurita America’s application team collected samples and did an onsite micro-examination. Then the samples were sent to their in-house laboratory for additional analysis. Kurita America collects these types of samples to identify which bacteria are active in the system. In this case, Kurita America recommended a bioaugmentation program to assist in removing the FOG in the system. Based on the analysis and a review of the customer’s needs, the aeration basin had become overloaded and biodeficient. Essentially, the bacterial population in the aeration basin was unable to thrive and remove the necessary contaminants in its current state. Kurita America recommended the blended microbial supplements of KURIBIO 8002 and KURIBIO 8018 to provide the much-needed micronutrients and specific bacteria designed to stabilize the system.

KURIBIO 8002 contains a combination of specially selected and patented microorganisms adapted to degrade FOG, especially designed for food processing wastewater applications that contain fats, oils, and grease. KURIBIO 8002 improves chemical oxygen demand (COD) removal efficiency and maintains plant stability by degrading the FOG. In addition, KURIBIO 8018 is a liquid formulation containing selectively adapted bacterial spores, enzymes, and degradable surfactants. Beneficial microorganisms in KURIBIO 8018 have an affinity to FOG and attach themselves to the contaminants and degrade those contaminants in place.

The facility was able to continue normal operations while Kurita America worked on improving the aeration basin capabilities by removing the FOG cap with bioaugmentation over 12 weeks. Long-term results are focused on avoiding any upsets in the future but knowing that Kurita American can deliver a proven solution.

Much of the success came from Kurita America’s ability to recognize the upset and by running the micro-examinations to identify the bacteria and recommend a product to combat the FOG overload. Patience is the key to any bioaugmentation support, and in this case, the Kurita America team set up a dosing schedule for the bacteria as well as the follow up micro-examinations that indicated that the health of the recovering aeration basin. Micro-examinations typically provide indicator microorganisms growth before the stark visual difference that took almost three months to realize. This improved operation will not slow down production or cease production to recover the aeration basin. This application is a one-time fix for an upset condition, so no additional long-term testing or dosing is needed to maintain the system outside of what the facility currently does.

Kurita America’s innovative technologies solved this long-term customer’s most complex challenges to deliver optimal results while conserving natural resources for a better, more sustainable world. Contact Kurita America today to learn more how we can help you with FOG issues and bioaugmentation.

About the Authors:

Shawn Dittrich is a senior account manager at Kurita America, working in the Upper Midwest. Shawn has over 15 years of experience in the water treatment industry. Shawn has a bachelor's degree from North Michigan University and is a Certified Water Technologist (CWT) and a member of the Association of Water Technologies (AWT).

Shawn Dittrich is a senior account manager at Kurita America, working in the Upper Midwest. Shawn has over 15 years of experience in the water treatment industry. Shawn has a bachelor's degree from North Michigan University and is a Certified Water Technologist (CWT) and a member of the Association of Water Technologies (AWT).

Daryl Mandoza is a product manager for wastewater treatment solutions at Kurita America, specializing in liquid solid separation (LSS). He has a bachelor's and master's degree from Augsburg University and has worked in the water treatment industry for over 20 years.

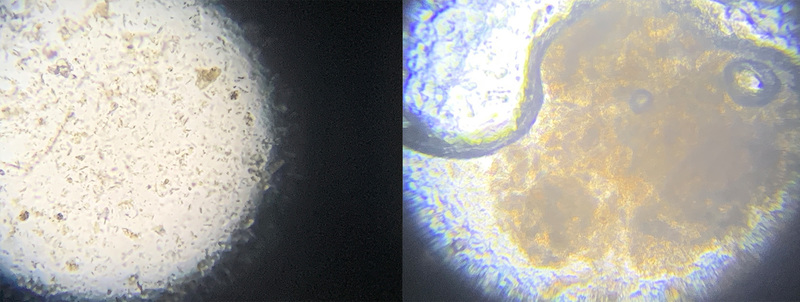

Microscopic exams (pictured above) help identify the bacteria population and health of the treatment system and next steps to improve efficiency.

Microscopic exams (pictured above) help identify the bacteria population and health of the treatment system and next steps to improve efficiency.  The picture on the left shows the aeration basin with an overload of FOG. The picture to the right shows the aeration basin approximately four weeks after supplemental bioaugmentation program was implemented.

The picture on the left shows the aeration basin with an overload of FOG. The picture to the right shows the aeration basin approximately four weeks after supplemental bioaugmentation program was implemented.