A washing machine manufacturer had accumulated a large amount of scale on their boilers, which was affecting their fuel consumption, overall costs, and steam efficiency, resulting in frequent boiler shutdowns. The manufacturer had two 600 horsepower firetube boilers that produced approximately 289 million pounds per year of steam. The steam was primarily used for styrene bead expansion and in the molding process to manufacture packaging foam that would encase the washing machines when being shipped across the globe.

T he previous water treatment provider was treating the manufacturer’s boilers with a phosphate-based program, but without a water softener system in front of the boilers to remove hardness, the phosphate program led to calcium phosphate scale.

he previous water treatment provider was treating the manufacturer’s boilers with a phosphate-based program, but without a water softener system in front of the boilers to remove hardness, the phosphate program led to calcium phosphate scale.

Kurita performed an initial site inspection of the manufacturer and found large quantities of scale in the boiler. If boilers are not treated correctly, excessive scale crystallization will deposit on the heat transfer surfaces.

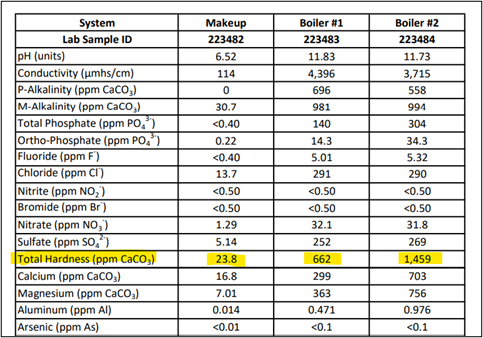

After the initial site inspection, Kurita returned for a comprehensive site assessment (CSA), including inspections, imaging, and testing. Samples were sent to Kurita’s in-house analytical laboratory. Because of the lack of a water softener in the system, there was over 250 parts per million (ppm) of calcium (Ca) in the cycled boiler water (graph below).

Based on the manufacturer’s current challenges, Kurita devised a plan to clean the boiler and soften the water entering the f acility. These two tasks needed to be done in tandem to stop the current hardness issues as well as descale the boiler.

acility. These two tasks needed to be done in tandem to stop the current hardness issues as well as descale the boiler.

Working with the customer and understanding their goals, the team chose Kurita’s DReeM Polymer™ technology to remove silicate and hardness scale from boiler surfaces. This award-winning chemistry works up to four times more efficiently than conventional polymers. It maximizes heat transfer surface cleanliness and prevents calcium hardness deposition. The polymer was fed into the dearator, which feeds directly into the boilers, allowing for cleaning during normal system operation.

While the DReeM Polymer was working in the boiler, Kurita also installed a water softener system to the makeup water. By having the system in place, most hardness was removed before entering the boilers. Kurita approached the customer concerns by first gaining an understanding of the overall situation and then providing both chemical and equipment solutions.

With DReeM Polymer feeding into the boiler, scale buildup was removed from the heat transfer surfaces. This enabled the system to run at optimal performance and no longer required high amounts of fuel. Additionally, the boilers no longer require frequent system shutdowns and appear to be running smoother than previously observed. In fact, a state inspector said, “This is the best these boilers have ever looked.”

Within the first four months, the manufacturer started to see savings between $10,000 and $13,000. Along with the fuel savings, the manufacturer reduced their CO2 production by 955 metric tons. Kurita ensures proper water softener system ability and DReeM Polymer dosages for the boilers.

Kurita continues to work with the washing machine manufacturer by looking into cooling water solutions. The manufacturer is also looking into a possible plant expansion, and Kurita is working at their side to provide water treatment solutions.

About the Author:

About the Author:

Account Manager Eric Townsend has been in the water treatment industry for nearly 20 years and has worked at Kurita America since 2021. He graduated from the University of Pittsburgh with a chemical engineering degree and is based in the South Carolina region. Eric has also Six Sigma Black Belt certification.