Biofuels Industry

Complete Plant and Process Solutions

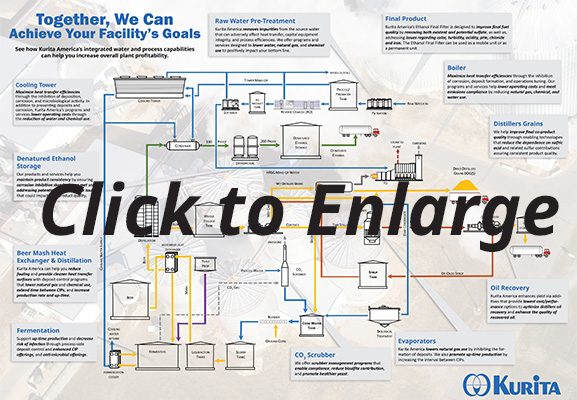

Kurita America has been an innovator in the biofuels industry since the beginning; pioneering new and ground breaking technology designed to keep you competitive. Our industry experience and thorough understanding of your operations allows us to provide complete solutions from fermentation to product quality, and everything in between. We work as a part of your team to eliminate the bottlenecks in your facility that affect quality, production and efficiency.Specialty Offerings

Identifying and updating equipment with out-of-date controls and automation can help ensure facility operations run uninterrupted. After our experienced representatives gain a complete understanding of your system equipment and regulatory restrictions, we will deliver an effective controls and automation upgrade plan specifically designed to achieve the facility’s goals and increase the lifespan and safety of any legacy equipment.

Kurita America's integrated products and services help maintain product consistency by ensuring corrosion inhibition standards are met and potential acidity and pHe issues are addressed, that could impact final product quality. In addition to biofuels water treatment, our solutions support up-time production and decrease risk of infection through process-side deposit control during fermentation, enhancing CIP offerings and anti-microbial offerings. Our scrubber management programs enable compliance, reduce bisulfite contribution and promote healthier yeast.

Kurita America's integrated products and services help maintain product consistency by ensuring corrosion inhibition standards are met and potential acidity and pHe issues are addressed, that could impact final product quality. In addition to biofuels water treatment, our solutions support up-time production and decrease risk of infection through process-side deposit control during fermentation, enhancing CIP offerings and anti-microbial offerings. Our scrubber management programs enable compliance, reduce bisulfite contribution and promote healthier yeast.

Kurita America can assist ethanol facilities to understand FSMA requirements, then develop and implement a compliant treatment program. Our unique chemistries provide maximum protection against scale and corrosion, while meeting FSMA compliance.

Environmental compliance regulations continue to become more stringent each year. As discharge limits are tightened, sometimes the only viable option to meet permit requirements is to eliminate discharge altogether. Our water reduction and reuse solutions have the ability to improve water quality, decrease water intake to a plant, and most importantly, significantly reduce liquid discharge to the environment. This can be done through a variety of chemical, equipment and engineering solutions.