Hospital Achieves Annual 350% Return with Kurita’s Cetamine® for Chilled Loop Systems

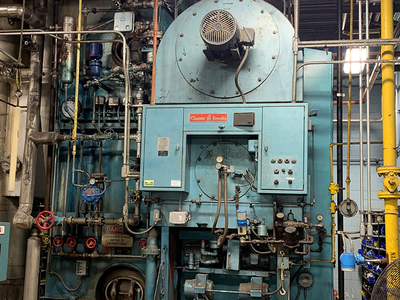

A large hospital has a campus wide seasonal chilled loop with approximately 75,000 gallons total volume. It was being treated using a traditional silica and azole-based corrosion inhibitor package. Corrosion coupon rates with the traditional inhibitor program were considered excellent for both mild steel and copper, yet each spring during startup, iron levels were found to be five to ten parts per million [...]

_reg.png)